Metalens Foundry Service

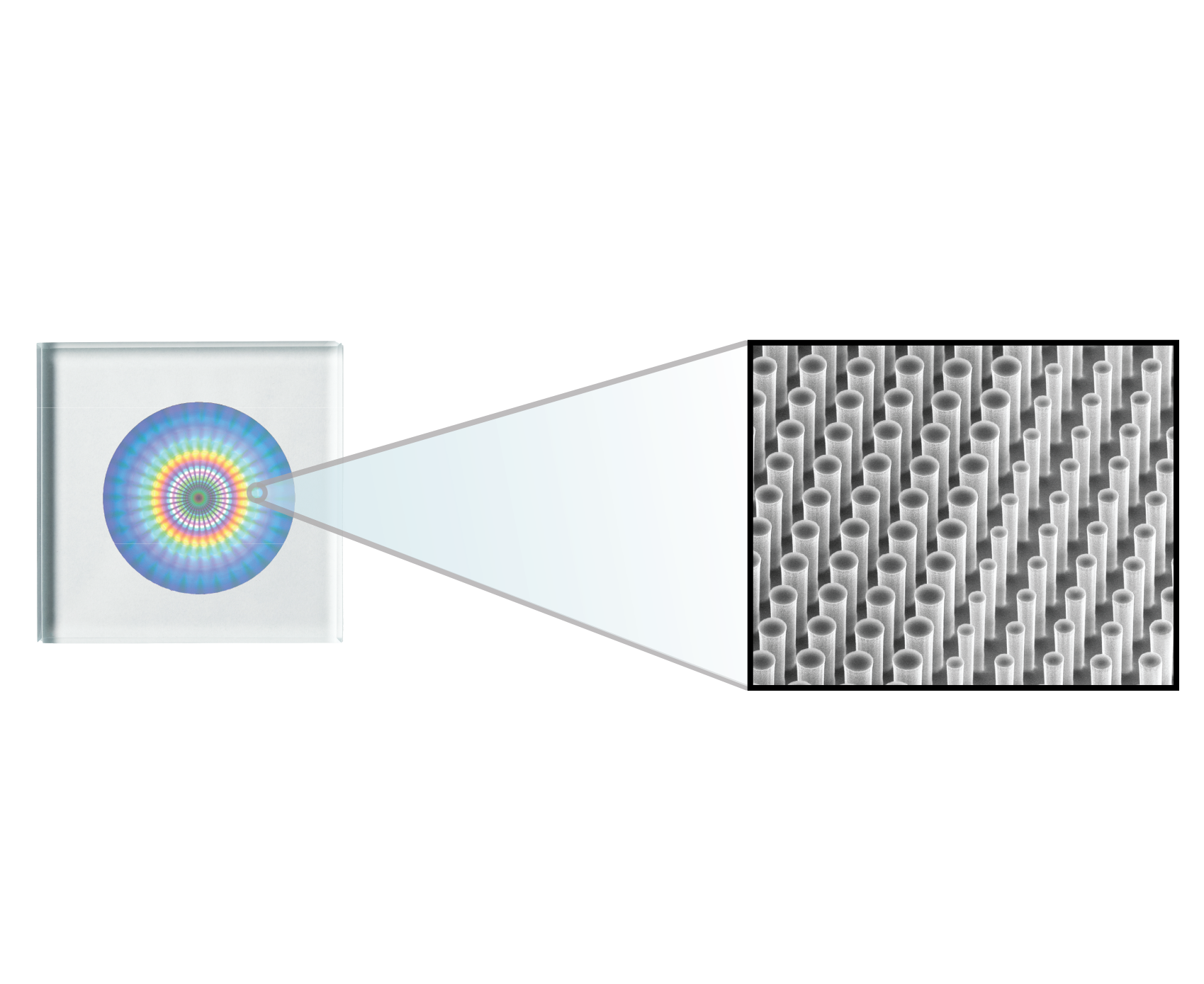

Moxtek manufactures high-performance metalenses for visible and IR wavelengths. Moxtek offers a full solution, including design, fabrication, measurement, and packaging capabilities. Our metalens design team can optimize the lens design to match custom applications. Our foundry service bridges the gap from research to production by offering prototyping and volume manufacturing.

Metalens benefits include reduced track length and weight in optical systems. They can have more design flexibility, added functionalities, shorter focal lengths and smaller diameters compared to traditional optics.

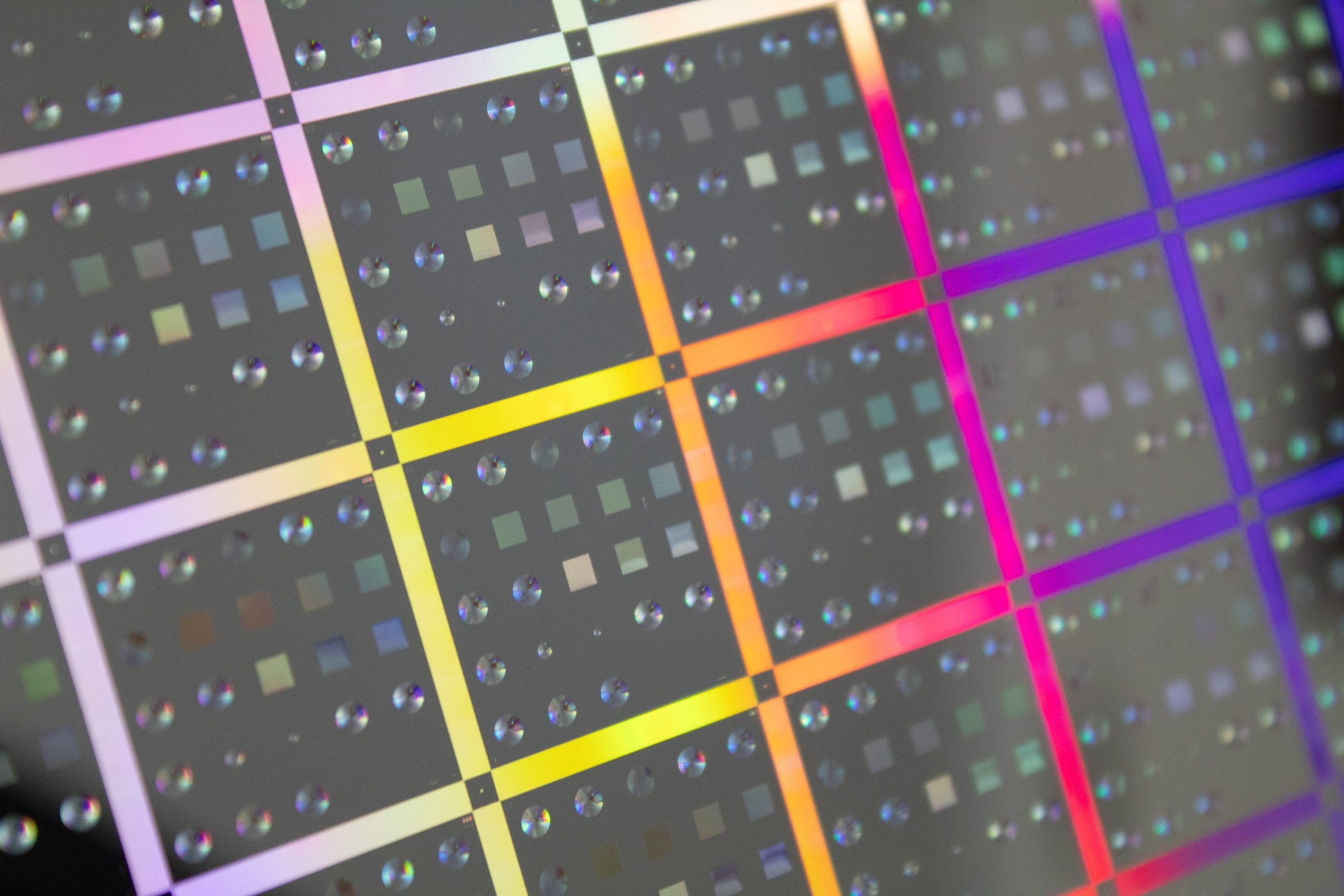

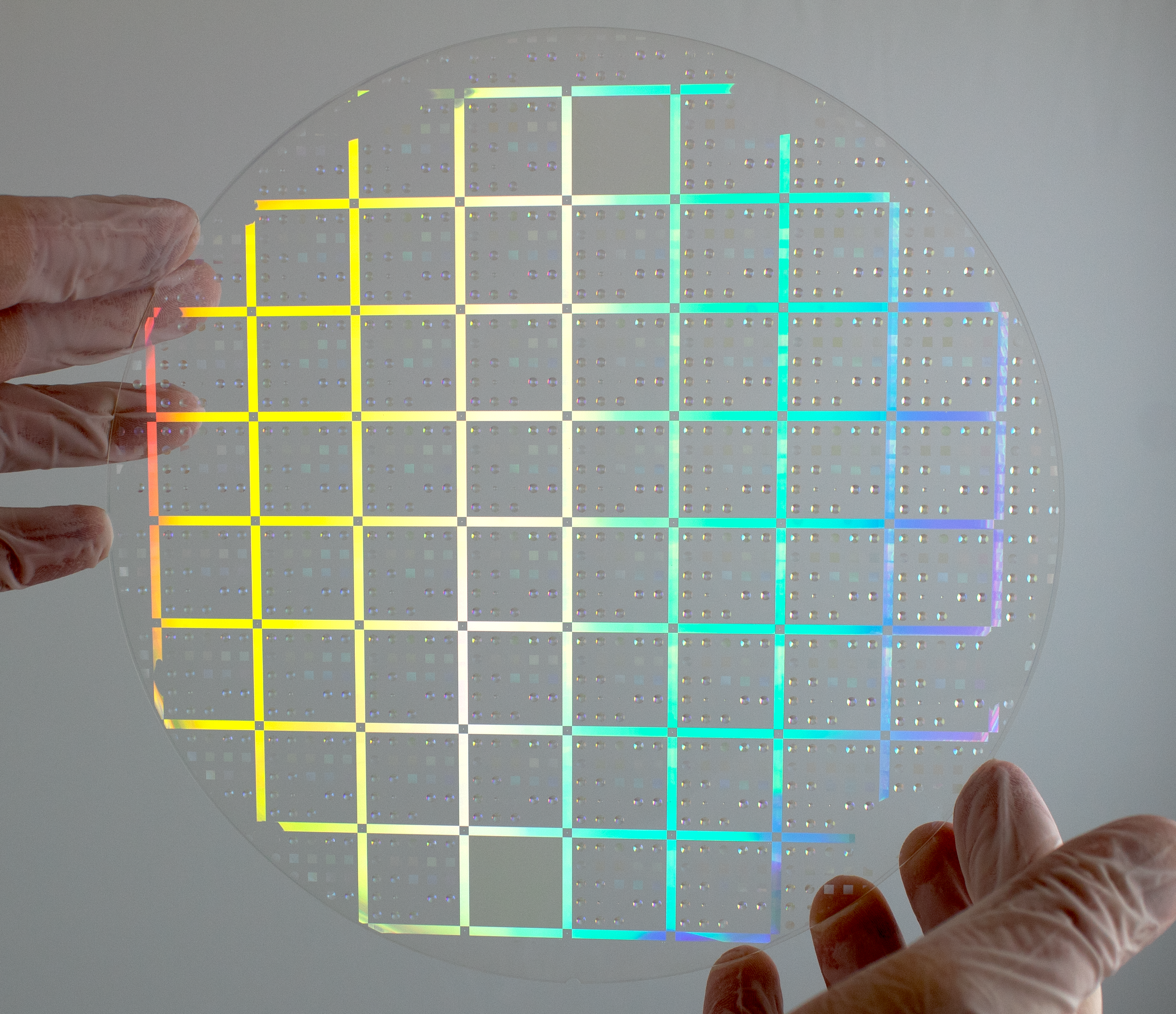

As a metalens company we have overcome various challenges associated with scaling up visible wavelength metalens manufacturing to production volumes. We have developed efficient methods to create masters combined with our existing NIL processing to provide a full solution approach to volume production. Moxtek replicates metalenses with extremely tight tolerances and high repeatability.

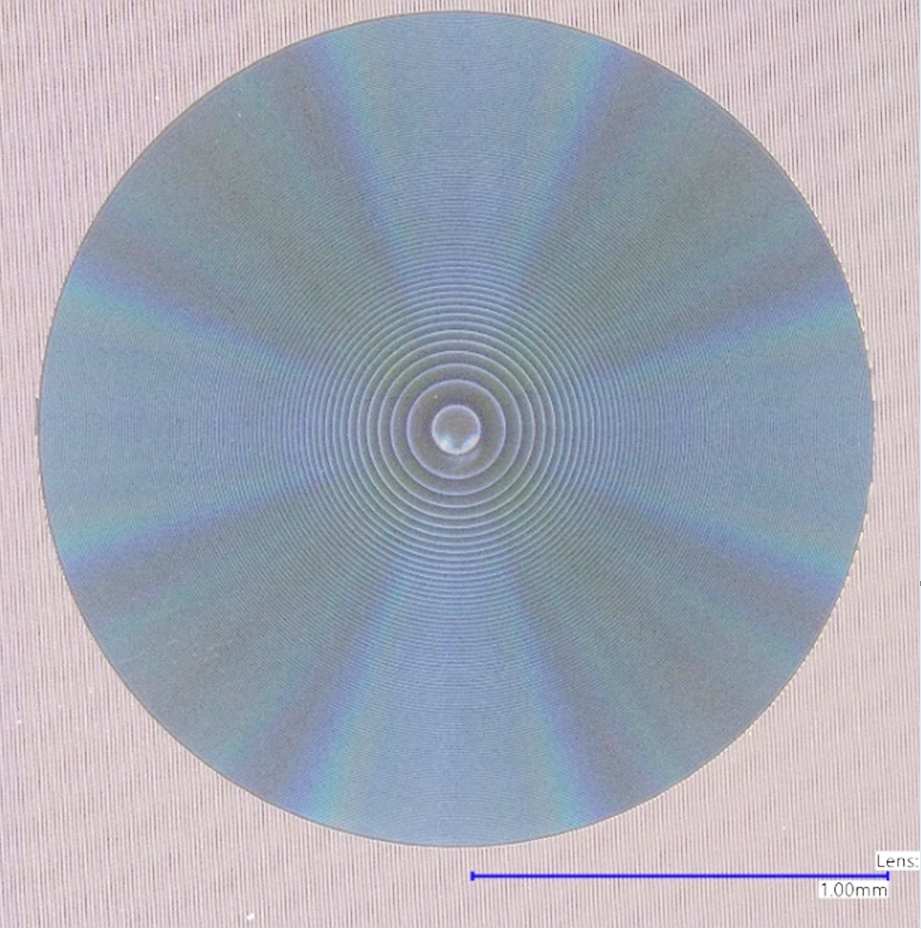

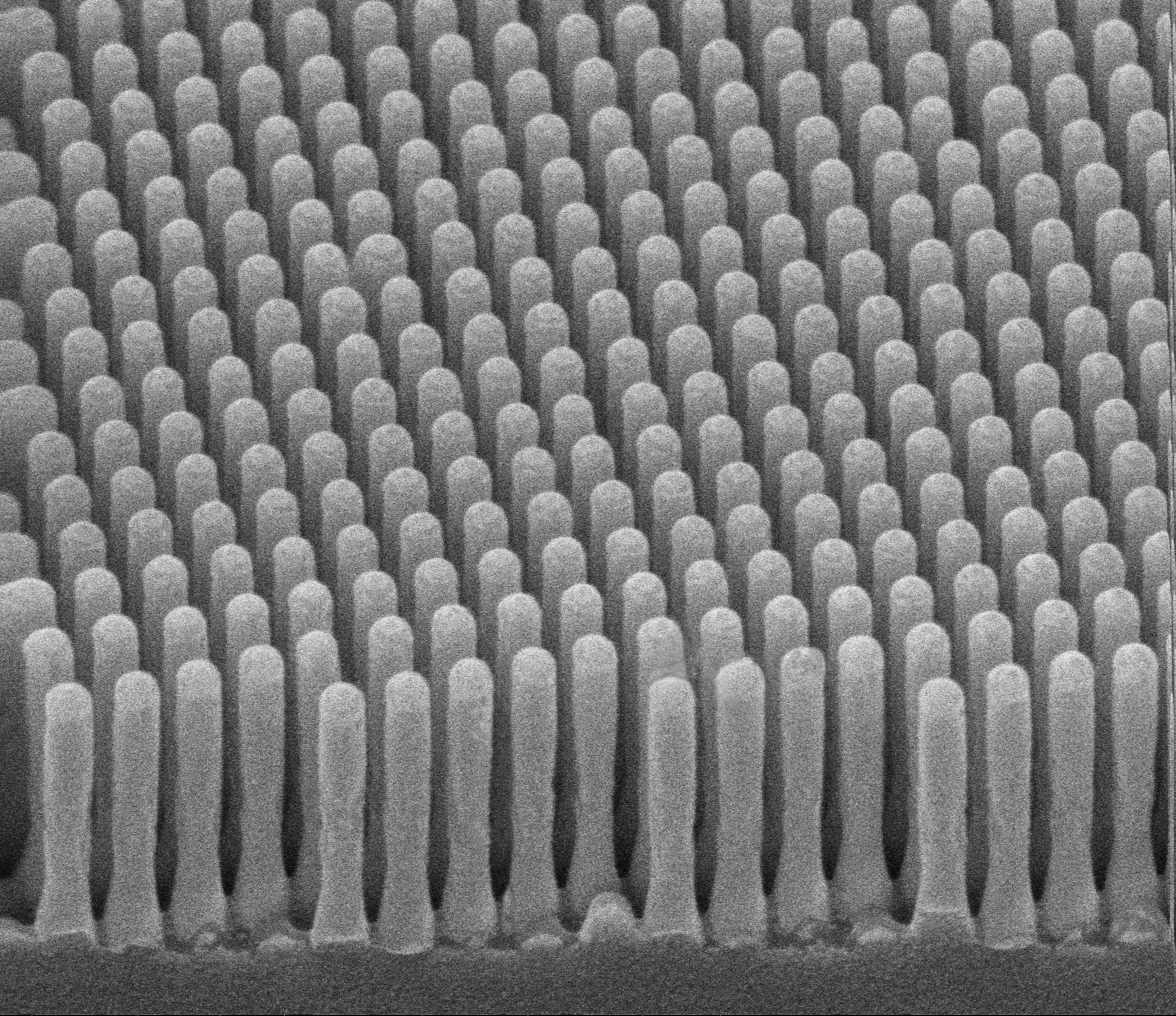

Moxtek’s manufacturing approach to high performance metalenses utilizes etching into high refractive index materials to obtain high aspect ratio nanostructures. Moxtek has produced a variety of visible metalenses with different sizes, focal lengths, numerical aperture, and operating wavelengths. Building on years of expertise, Moxtek has developed reliable methods to manufacture wafer-scale visible metalenses for various emerging applications.

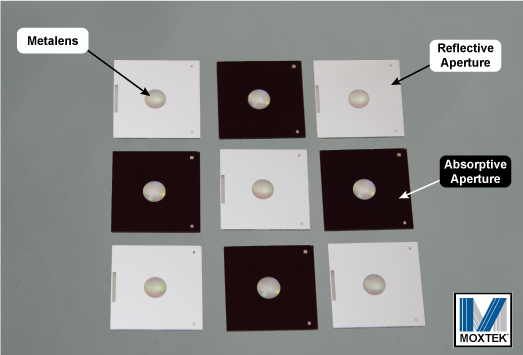

Moxtek’s metalens Overcoat™ protects against physical damage while boosting transmission. An absorptive aperture can be applied to cut down on stray light back reflections. Reflective aperture options are also available.

See our manufacturing parameters below.

For more information contact us here.

Metalens Datasheet Link