Design and assembly of micro-electronic hybrid packages including wirebonding, die bonding, bonding, and testing.

Every market calls for unique technological strides to solve real-world issues. And each solution requires a revolutionary core technology to get the job done. For the last 25 years, we’ve collaborated with geniuses like you to discover and develop the advanced core technologies that make ideas reality.

Design and assembly of micro-electronic hybrid packages including wirebonding, die bonding, bonding, and testing. Learn more

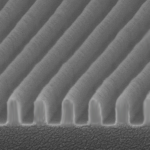

We have over 25,000 sq ft of cleanroom space equipped with lithographic tools, sputter tools, and etch tools, as well work areas equipped to manufacture optical assemblies. Learn more

We have over 25,000 sq ft of cleanroom space equipped with lithographic tools, sputter tools, and etch tools, as well work areas equipped to manufacture optical assemblies.

Our family of cleanrooms are versatile to accommodate the different specifications and manufacturing requirements of each project.

Do you need high voltage that meets limited space requirements? We specialize in creating power supplies that operate at voltages up to 70kV—in volumes smaller than a match box that can be powered with a battery. Learn more