Corrosion Resistance of DuraBeryllium Plus X-ray Windows Part 1

By Collin Hayward · App and Tech Notes · 25/03/14

DuraBeryllium® Plus windows are Moxtek’s most robust coated beryllium x-ray window. This window has an additional thin coating of polymer “Plus” applied to the already robust DuraBeryllium window. The Plus layer is more resistant to water and other harsh chemicals.

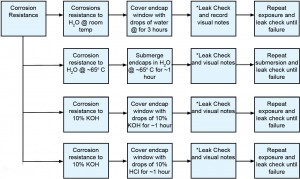

DuraBeryllium Plus windows successfully withstand continuous exposure to heated water as well as to other chemicals. A series of tests were completed on DuraBeryllium windows as seen in the test summary below. Part 1 of this application note details exposure of DuraBeryllium Plus to water, KOH, and HCl. Part 2 will be released later in 2012 and will include details of exposure of this window to other harsh chemicals.

Blank box= no data collected. X= damaged.

10% KOH Exposure at room temp

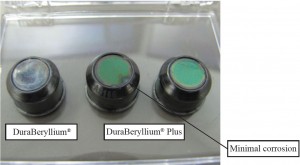

DuraBeryllium Plus and DuraBeryllium Visual image above of DuraBeryllium Plus and DuraBeryllium after exposure to HCl for ~3 hours. HCl speedily reacts under the surface of DuraBeryllium.

DuraBeryllium Plus and DuraBeryllium Visual image above of DuraBeryllium Plus and DuraBeryllium after exposure to HCl for ~3 hours. HCl speedily reacts under the surface of DuraBeryllium.

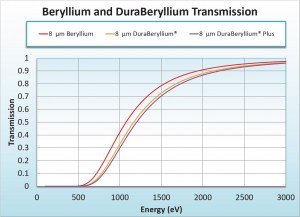

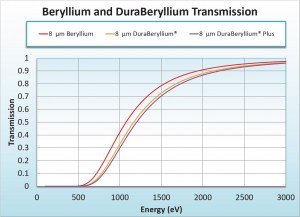

X-ray Transmission

DuraBeryllium protective layers provide corrosive shielding as well as a hermetic barrier to the beryllium foil. These protective layers are very thin and the resulting x-ray attenuation is equivalent to about 1μm of beryllium, having little impact on x-ray transmission. See chart below.

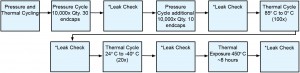

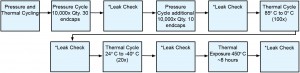

Pressure and Thermal Cycling

To demonstrate strength of the DuraBeryllium window, Moxtek pressure and thermal cycled thirty mounted windows. All thirty mounted windows were exposed to 10,000 cycles (15psi to atmosphere). Ten of these endcaps went through an additional 10,000 cycles. All windows withstood the pressure and thermal cycling without failure. The flowchart below details the testing procedure used.

Pressure and Thermal Cycling Testing Flow Chart

* Pass if helium leak tight <1.00 x 10-10 (mbar * L/sec)

Corrosion Resistance

8μm DuraBeryllium windows are very robust when continuously exposed to water at both room temperature and at 65º C. Conversely uncoated 8 μm beryllium windows will corrode when exposed to water within days. The flowchart below details the testing procedure used.DuraBeryllium When Exposed to Water

The table below shows the robustness of DuraBeryllium windows when exposed to water.| Pass (P) = He Leak Tight (<1 x 10-10 mbar * L/sec) | Leak Testing | |||||||||||

| ~60°C H2O | Room Temperature H2O | |||||||||||

| DuraBeryllium Plus | DuraBeryllium | DuraBeryllium Plus | DuraBeryllium | |||||||||

| Approx. Time Exposure | A0177 | A0156 | V311 | misc | A0159 | A0174 | A0168 | A0166 | A0153 | 3D | 4D | V3112 |

| 3 hours | P | P | P | P | P | |||||||

| 4 hours | P | P | P | |||||||||

| 5 hours | P | P | P | |||||||||

| 10 hours | P | P | P | P | P | P | ||||||

| 15 hours | P | P | ||||||||||

| 20 hours | P | P | P | P | P | |||||||

| 24 hours | P | P | P | |||||||||

| 2 days | P | P | P | P | P | P | P | P | P | |||

| 3 days | P | P | P | |||||||||

| 4 days | P | P | P | P | P | P | P | P | P | |||

| 6 days | P | P | P | P | P | |||||||

| 7 days | P | P | P | |||||||||

| 8 days | P | P | ||||||||||

| 11 days | P | P | P | P | P | P | P | P | ||||

| 14 days | P | P | P | P | P | |||||||

| 18 days | P | P | P | P | P | P | P | |||||

| 21 days | P | P | P | P | P | |||||||

| 1 month | P | P | P | P | P | P | P | P | P | P | P | P |

| 2 month | P | P | P | P | P | P | P | P | P | P | P | P |

| 3 month | P | P | P | P | P | P | P | P | P | P | P | P |

| 4 month | P | P | P | P | P | P | P | P | P | X | Fail | P |

| 5 month | P | P | P | P | P | P | P | P | P | P | ||

| 6 month | P | P | P | P | P | P | P | P | P | P | ||

Visual Observation

The images below were taken four months after exposure to H2O at room temperature. As seen in the images, there was some discoloration on the window coating but all windows were leak tight.KOH Exposure Test (Exposure = 1 week)

Under extreme KOH exposure for one week, DuraBeryllium Plus did not develop any leaks. Some visual polymer delamination was observed after 6 days. Prolonged exposure to KOH will eventually dissolve the polymer “Plus” layer.| Leak Testing Results | |||

|---|---|---|---|

| 10% KOH | |||

| Time Exposure | DuraBeryllium Plus | DuraBeryllium | |

| A0172 | A0154 | no number | |

| 3 hours | P | P | P |

| 4 hours | P | P | - |

| 5 hours | - | - | - |

| 6 hours | P | P | P |

| 10 hours | P | P | - |

| 15 hours | P | P | - |

| 20 hours | - | - | - |

| 24 hours | - | - | P |

| 2 days | P | P | - |

| 3 days | - | - | P |

| 4 days | - | - | P |

| 6 days | P | P | |

| 7 days | P | P | |

HCl Exposure Text (Exposure = 1 week)

HCl reacts quickly with bare beryllium and corrodes 8μm Be windows within minutes. Both DuraBeryllium Plus and DuraBeryllium add some resistance to this harsh chemical but only for a few hours, as seen in the table below.| Leak Testing Results | |||

|---|---|---|---|

| 10% HCl | |||

| Time Exposure | DuraBeryllium Plus | DuraBeryllium | |

| A0160 | A0179 | misc | |

| 3 hours | F | P | F |

| 3 hours | F | ||

DuraBeryllium® Plus and DuraBeryllium®

Visual image above of DuraBeryllium Plus and

DuraBeryllium after exposure to 10% HCl at room temperature for ~3 hours. HCl

speedily reacts under the surface of DuraBeryllium.