Improving the Hermetic Seal on Moxtek’s AP3 Window

By Collin Hayward · App and Tech Notes · 4/03/14

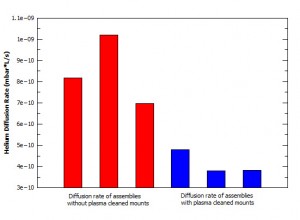

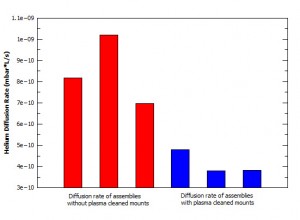

Moxtek® is a leading manufacturer of X-ray windows for low energy X-ray detection. Moxtek manufactures ultra-thin polymer X-ray windows that are attached to metal mounts which house energy dispersive X-ray detectors such as Silicon Drift Detectors (SDDs). These windows allow for transmission of low energy X-rays while maintaining a hermetic seal critical for the X-ray detector’s performance. While Moxtek ensures that all windows meet published limits for leak rates, no material is a perfect gas barrier and gasses will diffuse through window assemblies over time. As a continuous improvement effort, Moxtek investigated the effects of plasma cleaning the metal mounts before attaching a window, and achieved around a 40% reduction in the diffusion of helium through the epoxy-to-mount interface.

Introduction

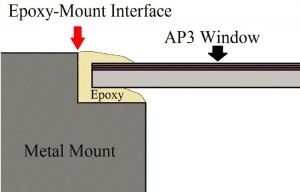

One of the primary functions of an X-ray window is to act as a gas barrier. It is well known that no material is a perfect gas barrier. Gasses diffuse at different rates through materials depending on many factors. Diffusion was measured at different locations on the window assembly and the epoxy-to-mount interface was identified as a significant source of diffusion. Efforts were made to reduce diffusion at the epoxy-to-mount interface. Moxtek evaluated the leak rate of helium in a window blank and metal mount assembly. The window blank was used to eliminate the diffusion signal from the thin polymer film, thereby concentrating on the diffusion through the metal-to-window frame seal. Helium is an industrial standard in vacuum leak detection. Helium is a small, inert molecule; a reduction in the diffusion of helium through Moxtek window assemblies is a good indicator that the diffusion of other gasses should be reduced as well. Surface conditions on the metal mount, such as contamination and surface energy, play a key role in adhesion of the epoxy to the mount which effects gas permeability. The effects of different plasma cleaning processes on the surface of the metal mounts were also evaluated by Moxtek in order to optimize adhesion of the epoxy to the mount.Methods

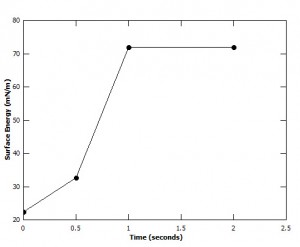

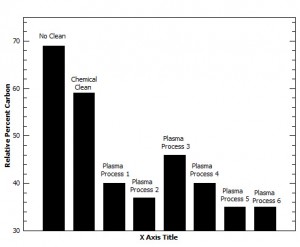

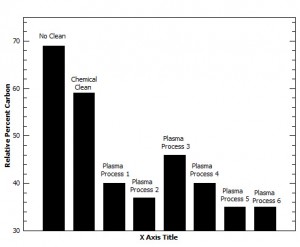

Diffusion of helium through Moxtek AP3 window assemblies was measured by using a fixture designed to eliminate the effects of helium diffusing through anything other than the area of interest, and by using a window blank to isolate diffusion through the metal-window frame seal. Window assemblies were exposed to helium for long periods of time until a steady state diffusion rate was achieved. The epoxy-mount interface was one area identified as a source of diffusion (Figure 1). In order to reduce diffusion of gasses through the epoxy-mount interface, plasma cleaning the mounts was investigated as a way to reduce surface contamination on metal mounts and to increase wettability of the epoxy. SEM/EDS analysis was done to check for possible contamination on the metal mount before and after plasma cleaning. XPS was done to compare plasma cleaning processes and a chemical cleaning in their effectiveness in removing contamination. Wettability of the epoxy on the metal mount was evaluated by checking the surface tension of the metal surface using dyne solutions. Finally, solid metal disks were epoxied into window mounts so that all interfaces with the epoxy would be epoxy-to-metal. Some mounts were plasma cleaned prior to attaching while others were not. All parts were then evacuated on the vacuum side and then exposed on the other side to 1 atm of helium for 10 hours allowing a steady state diffusion to occur. Diffused helium was detected using a helium leak detector.Results

Figure 3 Relative percent carbon measured by XPS on metal window mounts that were cleaned by different processes

Figure 5 Difference in steady state diffusion of helium from mounts that were treated with plasma prior to attaching metal blank and those that were not